The Essential Role of the Water Pump on Engine Performance

The water pump on engine is a vital component that ensures the efficient functioning of both gasoline and diesel engines. Understanding its role not only helps in mitigating potential issues but also enhances overall automotive knowledge. In this article, we will delve deep into the particulars of the water pump, its significance, working principles, and the best maintenance practices to extend its life and improve engine efficiency.

What is a Water Pump?

A water pump is a mechanical device designed to move coolant through the engine's cooling system. It plays a crucial role in regulating engine temperature, ensuring that your vehicle operates efficiently and safely. The water pump circulates the coolant to absorb heat from the engine and then directs the heated coolant to the radiator, where it dissipates the heat and recirculates back to the engine block.

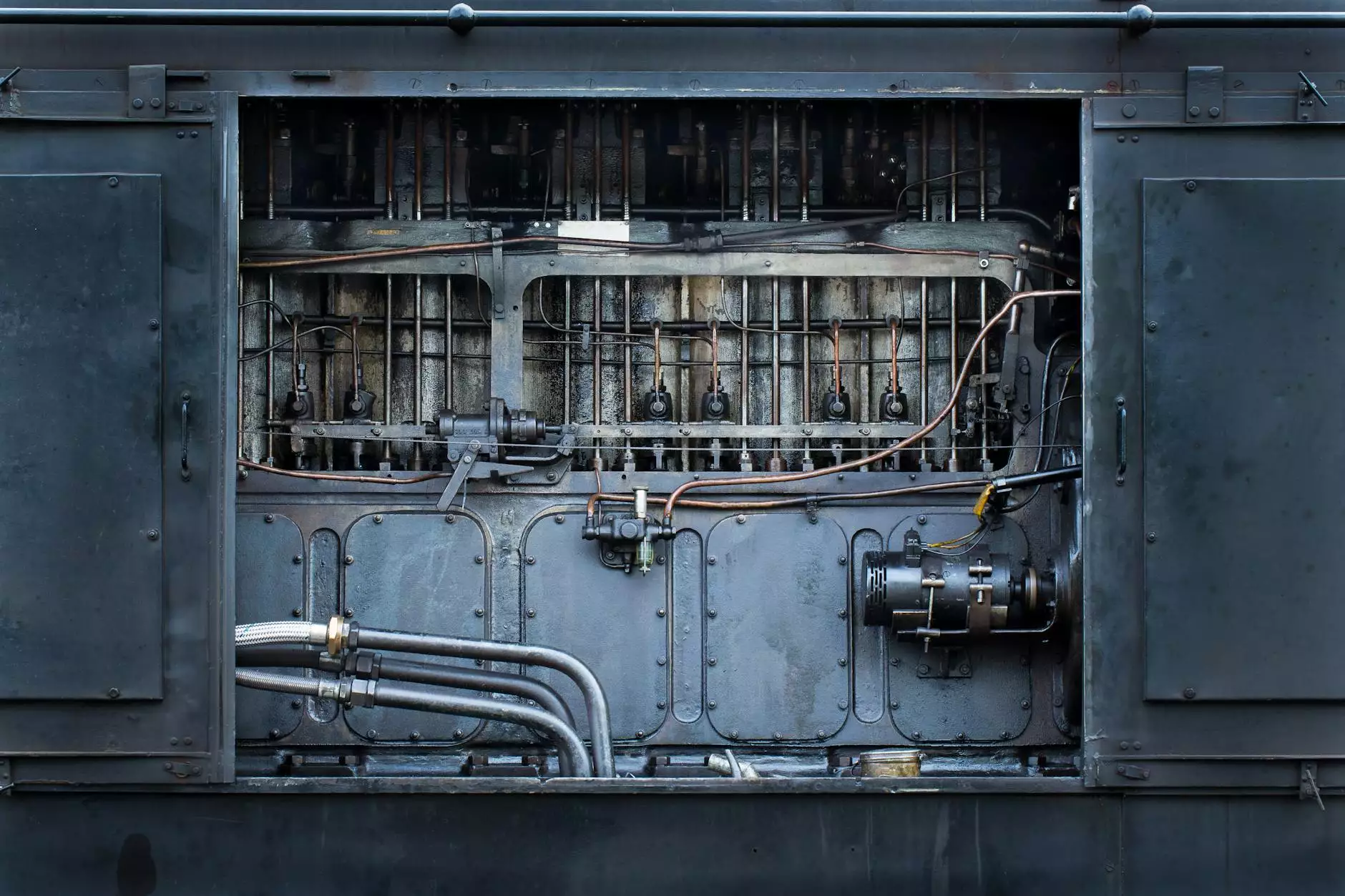

Components of a Water Pump

Understanding the various components of the water pump on engine can help in diagnosing issues and monitoring its performance. The main components include:

- Impeller: The impeller is a rotating part of the water pump that facilitates the movement of coolant. Its design and material can affect the efficiency of the pump.

- Housing: The housing encloses the impeller and directs coolant into and out of the pump. A durable, corrosion-resistant material is typically used to fabricate the housing.

- Seal: The seal prevents coolant leakage, ensuring the pump operates efficiently without losing fluid. Over time, seals can wear out and lead to pump failure.

- Bearing: Bearings support the rotating impeller and reduce friction. When bearings wear out, they can produce noise and affect the pump’s performance.

- Drive Mechanism: Most water pumps are operated by a belt connected to the engine’s crankshaft. Understanding this mechanism is crucial for maintenance.

How Does the Water Pump Affect Engine Performance?

The water pump on engine dramatically influences performance, efficiency, and longevity. Here are several key impacts:

1. Temperature Regulation

By effectively circulating coolant, the water pump helps maintain optimal operating temperatures. When the engine runs too hot, it can cause significant damage, including:

- Engine Knock: Excessive heat can lead to pre-ignition.

- Warped Cylinder Heads: Overheating can warp vital components.

- Coolant Boiling: Prolonged high temperatures can cause coolant to boil, leading to overheating.

2. Fuel Efficiency

When an engine operates at too high a temperature, thermal efficiency decreases, leading to poor fuel economy. A functioning water pump allows the engine to maintain an ideal temperature range, maximizing fuel efficiency.

3. Engine Longevity

Proper temperature regulation by the water pump on engine helps reduce wear and tear on engine components, extending the overall lifespan of the engine. Regular maintenance of the water pump can prevent costly repairs down the line.

Signs of a Failing Water Pump

Recognizing the signs of a failing water pump can save you from severe engine damage. Common symptoms include:

- Coolant Leaks: Visible puddles or dripping fluids beneath the vehicle indicate potential seal or housing failures.

- Overheating: If your engine temperature gauge shows higher than normal levels, it may be due to an ineffective water pump.

- Noisy Operation: Grinding or whining noises can suggest bearing failure within the pump.

- Steam or Smoke: Excessive steam from the engine compartment indicates severe overheating, often linked to water pump issues.

Maintenance Tips for Your Water Pump

To ensure the longevity and effectiveness of the water pump on engine, consider implementing the following maintenance tips:

1. Regular Inspections

Regularly inspect your water pump and cooling system for any signs of wear, leaks, or corrosion. Look for signs of coolant leaks under the vehicle and check the condition of belts and hoses connected to the water pump.

2. Coolant Changes

Flush the cooling system and replace the coolant according to your manufacturer's recommendations. Deteriorated or contaminated coolant can lead to overheating and damage to the water pump.

3. Monitor Engine Temperature

Keep an eye on the engine temperature gauge. If it consistently runs hotter than normal, investigate the cause, as it could indicate a failing water pump or other cooling system issues.

4. Check for Unusual Noises

Listen for any unusual noises coming from the engine bay. If you hear whining or grinding sounds, have your water pump evaluated as soon as possible.

5. Replace as Necessary

Water pumps are subject to wear and should be replaced as part of regular maintenance schedules. If you notice any signs of failure, it's best to address the issue promptly to avoid engine damage.

Choosing the Right Water Pump for Your Diesel Engine

When selecting a water pump, particularly for diesel engines, consider the following factors:

- OEM vs. Aftermarket: Original Equipment Manufacturer (OEM) parts often offer better compatibility and reliability compared to aftermarket alternatives.

- Material Quality: Look for pumps made from high-quality materials that resist corrosion and wear.

- Warranty: A good warranty can provide peace of mind regarding the water pump's longevity and reliability.

At client-diesel.com, we provide high-quality diesel engine parts, including durable and reliable water pumps. Our commitment to quality ensures that you receive products that enhance your engine's performance and longevity.

Conclusion

The water pump on engine is more than a simple component; it is an essential element that plays a vital role in your vehicle's overall performance, efficiency, and longevity. Regular maintenance and timely replacements can prevent severe trouble and ensure that your diesel engine runs smoothly. Invest in quality parts and pay attention to your engine's temperature and overall health. For reliable spare parts, including top-rated water pumps, explore our offerings at client-diesel.com to ensure your engine runs as smoothly as possible.